Once again it’s been much too long since our last report! As I started this, I remembered why—there’s been a change in the way Google Photos integrates with WordPress, and it’s pretty tedious trying to get photos across. Excuses excuses…

It was a great summer, with excellent winds for sailing, and our members who took their own boats cruising up the coast enjoyed a lot of great times. We’ve made great progress on our Handliner, and it’s been a challenging build!

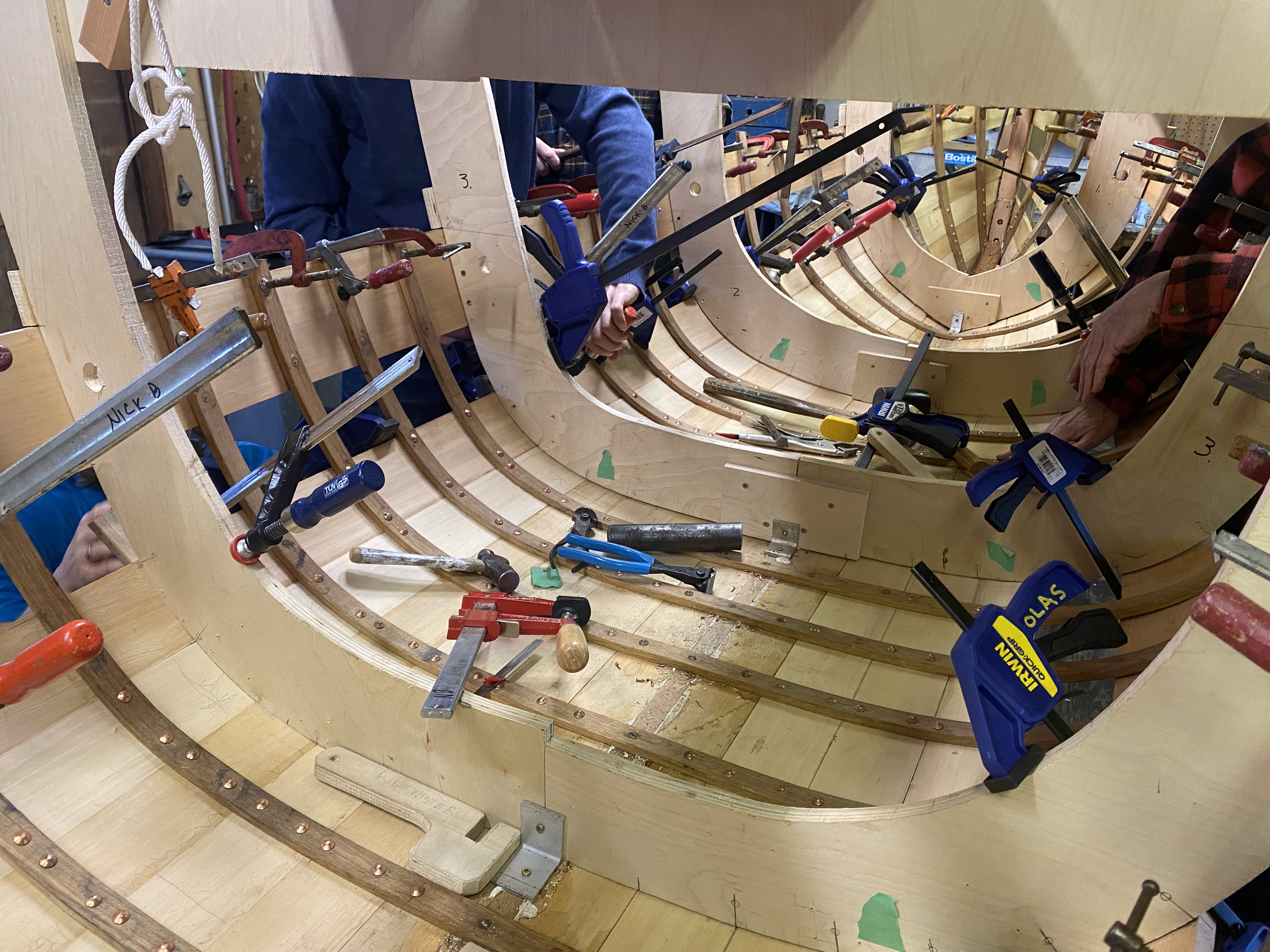

Since last post, we’ve been busy fitting and riveting planks. One of our challenges was that we discovered that our ribs had not been sufficiently bent into shape, due to the ribbands not being quite sturdy enough to hold them. We removed the rivets at the sheer strake and re-steamed the ribs using a wallpaper steamer and a vacuum cleaner hose, bending them to better meet the planks.

We marched our way up the boat since then, milling our planking stock, patterning and fitting the planks, with the help of some steam, and finally riveting them into place.

Last week we fit and fastened the final plank!! There are still ribs to fit, where we removed the moulds, so those were not the last of the rivets, but all the planks are now in place and mostly fastened. We celebrated with the traditional shot of whiskey, and promptly removed the moulds, revealing the shape of the boat. We’re pretty pleased!!

An enormous boost to productivity and confidence is the addition of new flotation!!!!! We had purchased the blocks earlier in the year, and 8 bricks of 700 lb floatation each, for a total of 5,600 lbs. were installed in November, thanks to the crew from Skookum Yacht Services on Granville Island. Our wharfinger Matt is part of that crew, and was instrumental in arranging their day at (or rather under ) our shop. HUGE thank you to the crew!! In appreciation, we’ll be varnishing their handliner when the weather becomes more suitable.

Our annual Heritage Harbour Classic in September was a fantastic success, with gorgeous weather, a great turnout, and a decent breeze!

We had our whole fleet of 4 OLAS sailboats racing, and 1 rowboat out as a media boat, with Bernie getting some great photos and videos out in Vogler. 6 of the other sailboats from the harbour were racing, and 3 powerboats carried officials and observers out into the action. We missed the 4 other racers who couldn’t make it for one reason or another. Next year!

The race result was Ricochet in 1st, Sonja’s Spirit 2nd, and Winsome III coming 3rd. Sula was next, only 18 minutes behind the winner. Button Swan was 2nd in the small boats, followed by Enke then Ragna battling for 3rd.

We had our usual mayhem in the rowing race, with a lot of fun for the spectators and several of the competitors. The tossing of the heaving line was hotly contested, with a few surprises.

A huge thank you to Bruce, Matt, and the Vancouver Maritime Museum for hosting this great event, to Rob and others grilling our burgers, to the Museum for the awesome t-shirts, and to the the rest of the Heritage Harbour community for making this such a fabulous time.

We were invited to show our work at the Bard on the Beach a couple of times during the summer, and enjoyed the challenge of bringing our boat and display items over to Vanier Park, and chatting with their patrons about our club.

That about catches us up with our work at the shop—hope to see you down there!